Our Processes

CAD, manufacturing-oriented building component design & reverse engineering

Our Processes

- Selective Laser Sintering (SLS)

- Powder Bed Fusion (MJF/SAF/HSS)

- Stereolithography (SLA)

- PolyJet (PJM) -EN

- CAD, manufacturing-oriented building component design & reverse engineering

- Measurement technology

- Metal casting

- Selective laser melting (SLM)

- RapidTooling (RT)

- CNC Machining

- Model making (MB)

- Vacuum casting (VAC)

- Fused Deposition Molding (FDM/FFF)

Whether you need detailed solutions or complex assemblies, cirp supports you throughout the entire product development process:

“From idea to product!”

We combine technical precision with creative passion. Our aim is to make your product development more efficient, sustainable, and innovative—from the initial idea to series production. Through interdisciplinary thinking, state-of-the-art tools, and close communication with our customers, we create solutions that impress.

Together, we develop products that set standards:

– innovative, functional, and ready for the market –

We look forward to turning your challenge into a successful result.

cirp – your partner for innovative product development.

Co-Engineering

Together from idea to product

Our 3K development – your path to an innovative product

At cirp GmbH, we support your product development with a clearly structured and proven process – 3K: conception, construction, and creation. From the initial idea to detailed planning and the finished product, we focus on maximum precision, creativity, and technical expertise.

We transform your visions into tangible reality:

- During the conception phase, we work with you to develop innovative ideas and tailor-made solutions.

- During the design phase, we work out the concepts precisely and in detail.

- And during the creation phase, we turn your product into a prototype or model – efficiently, creatively, and with technical perfection.

Trust in our experience and commitment to successfully bring your project to life.

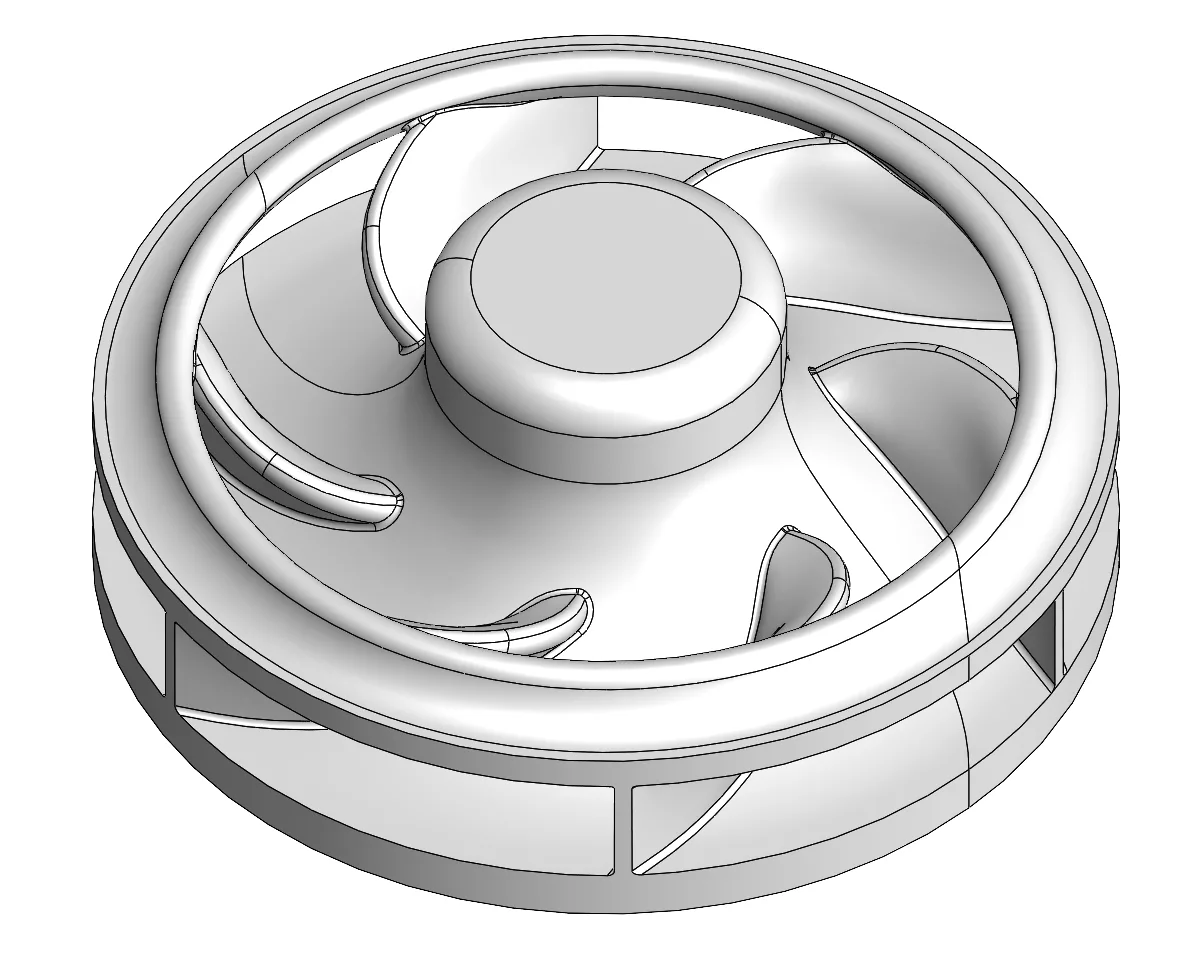

Construction for RapidTooling – Design that works

During the design phase, we already consider (small) series production using rapid tooling.

Our experience in the plastics processing industry enables us to design components that are suitable for injection molding, efficient, and economical right from the start. Every detail—from wall thicknesses, radii, and draft angles to the injection point—is specifically designed to achieve optimal results in subsequent production.

This results in designs that impress:

– technically sophisticated, suitable for production, and cost-optimized –

With our expertise, you avoid expensive adjustments and ensure the quality, functionality, and cost-effectiveness of your product.

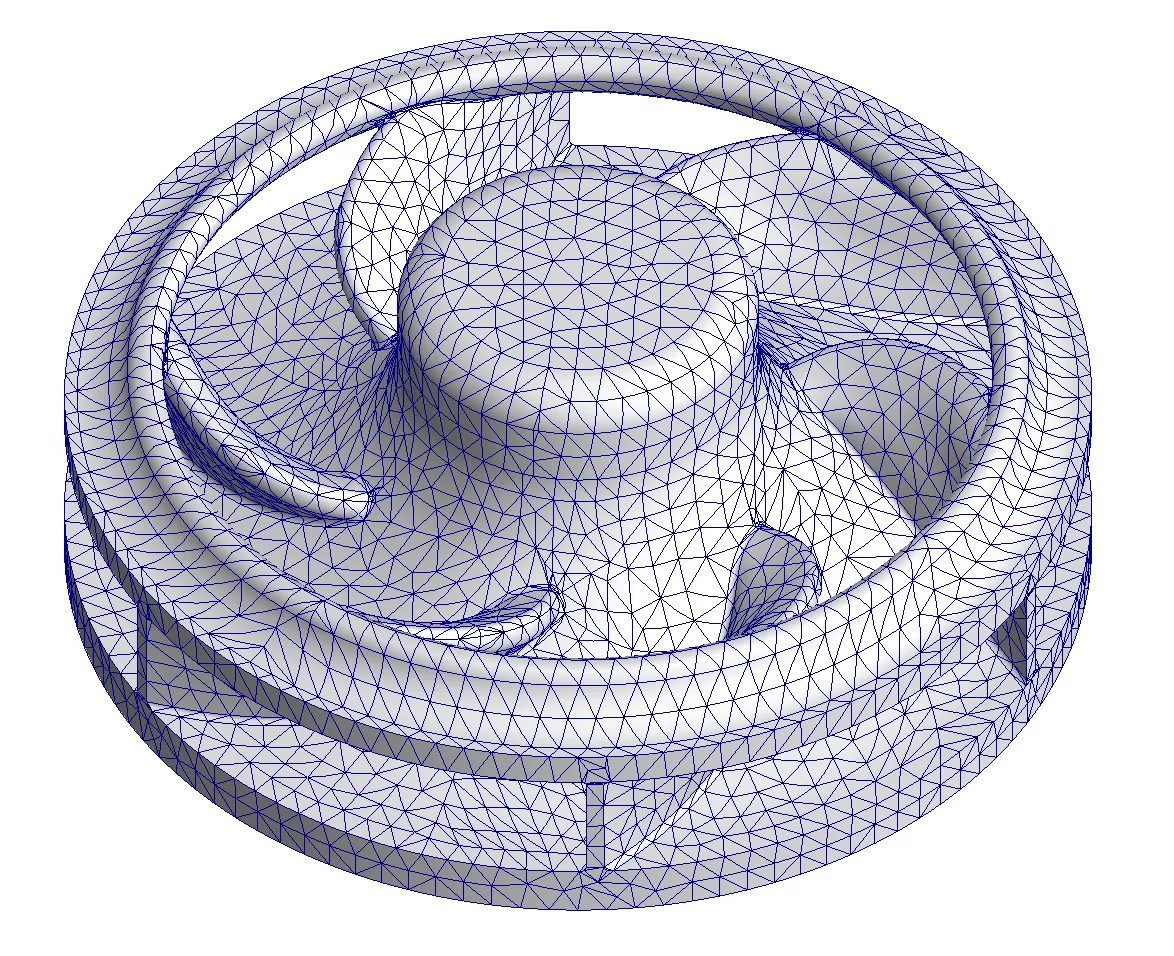

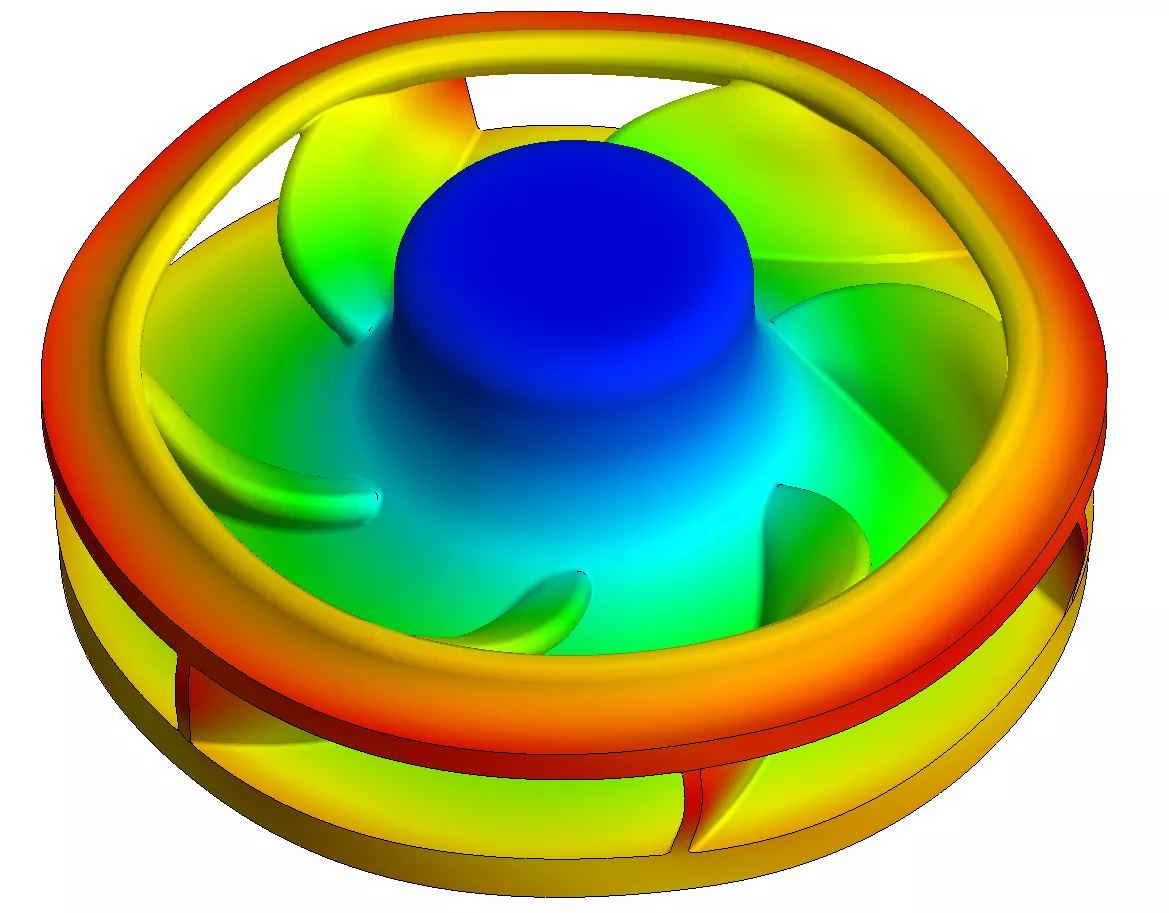

FEM – Analysis & Topology Optimization

Precision meets efficiency

Using state-of-the-art FEM analysis, we simulate the behavior of your components under real conditions—even before the first prototype is created.

We analyze loads, stresses, and deformations and use this information to derive targeted optimizations. Through topology optimization, we design structures that are lighter and more efficient—without compromising on function.

The result:

– Maximum stability with minimum material usage –

This is how we get your products right—technically perfect, economically viable, and future-oriented.

3D scanning and reverse engineering

Understanding reality digitally

Often, components exist—but there is no CAD data for them. Perhaps an existing product needs to be optimized, a spare part reproduced, or a tool checked. This is exactly where reverse engineering comes into play: it enables physical objects to be digitized precisely and used again as the basis for development and manufacturing.

Using state-of-the-art 3D scanning technology, we capture geometries in detail and convert them into precise CAD data. Whether for reverse engineering, quality control, or digitization of existing components, we create the basis for precise further developments and reproducible results.

We rely on high-resolution optical strip light scanners and digital 3D measuring systems:

This is how we combine speed, accuracy, and flexibility—from delicate individual parts to large-volume components. The collected data is used to create a digital model that can be analyzed, optimized, and redesigned.

– Precise, reproducible, and future-proof –

We bring the real world into the digital world—and make your products fit for the future.