Our Processes

Measurement technology

Our Processes

- Selective Laser Sintering (SLS)

- Powder Bed Fusion (MJF/SAF/HSS)

- Stereolithography (SLA)

- PolyJet (PJM) -EN

- CAD, manufacturing-oriented building component design & reverse engineering

- Measurement technology

- Metal casting

- Selective laser melting (SLM)

- RapidTooling (RT)

- CNC Machining

- Model making (MB)

- Vacuum casting (VAC)

- Fused Deposition Molding (FDM/FFF)

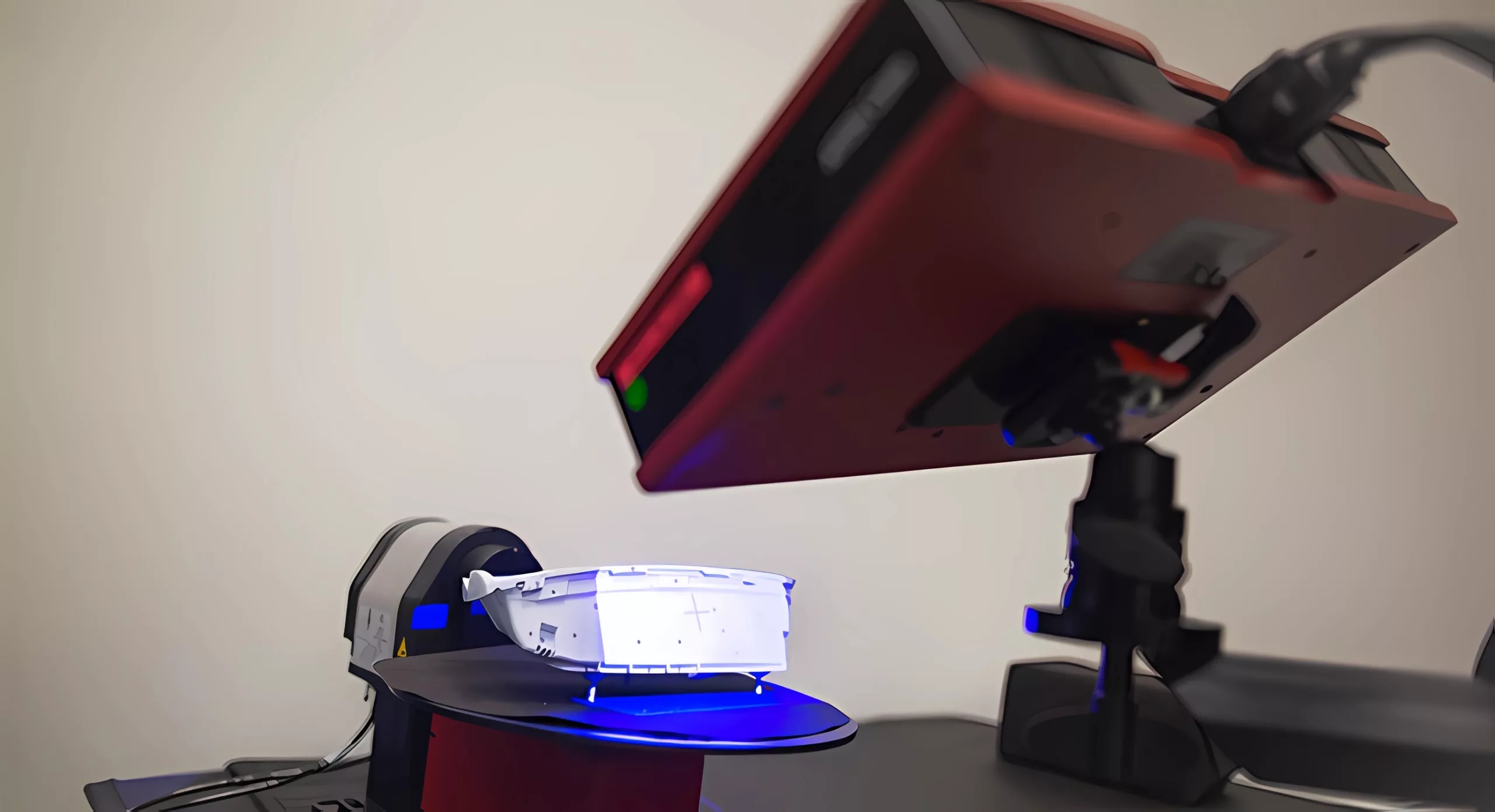

Measurement technology at the highest level—precision, quality, and compliance with standards

We are your reliable partner for precision measurement technology, quality assurance, and 3D digitization. With decades of experience and state-of-the-art technology, we capture, analyze, and evaluate components of all sizes and complexities—from dimensional inspection to highly complex geometries.

Our measurement technology services:

- 3D digitization

High-precision capture of your objects with the ATOS Core 3D scanning system from GOM-Zeiss – contactless and true to detail. Ideal for quality inspections, archiving, and production preparation. - Quality assurance & geometric evaluation

Comprehensive geometric and dimensional inspections, including form and position tolerances in accordance with current ISO GPS standards, as well as target/actual comparisons. - Tactile coordinate measuring technology (CMM)

Dimensional and geometric inspections with various probing systems for maximum precision. - Surface measurement & roughness testing

Determination of roughness values and surface quality according to standards. - Initial sample test reports (VDA Volume 2)

Creation of standard-compliant test documents to validate your manufacturing processes. - Industrial computed tomography (CT)

Precise analysis of highly complex geometries and independent evaluation with powerful software. - Reverse Engineering

Digital reconstruction of components for analysis, optimization, or reproduction.

Why we are your measurement technology experts:

We combine state-of-the-art measurement systems, comprehensive expertise, and decades of experience. Whether simple measurement tasks or highly complex testing processes—we deliver reliable, standard-compliant results that ensure your quality standards.

Your component deserves precise measurement technology

We deliver it—accurately, efficiently, and reliably.

3D digitization systems

GOM – ATOS Core 135

GOM – ATOS Core 300