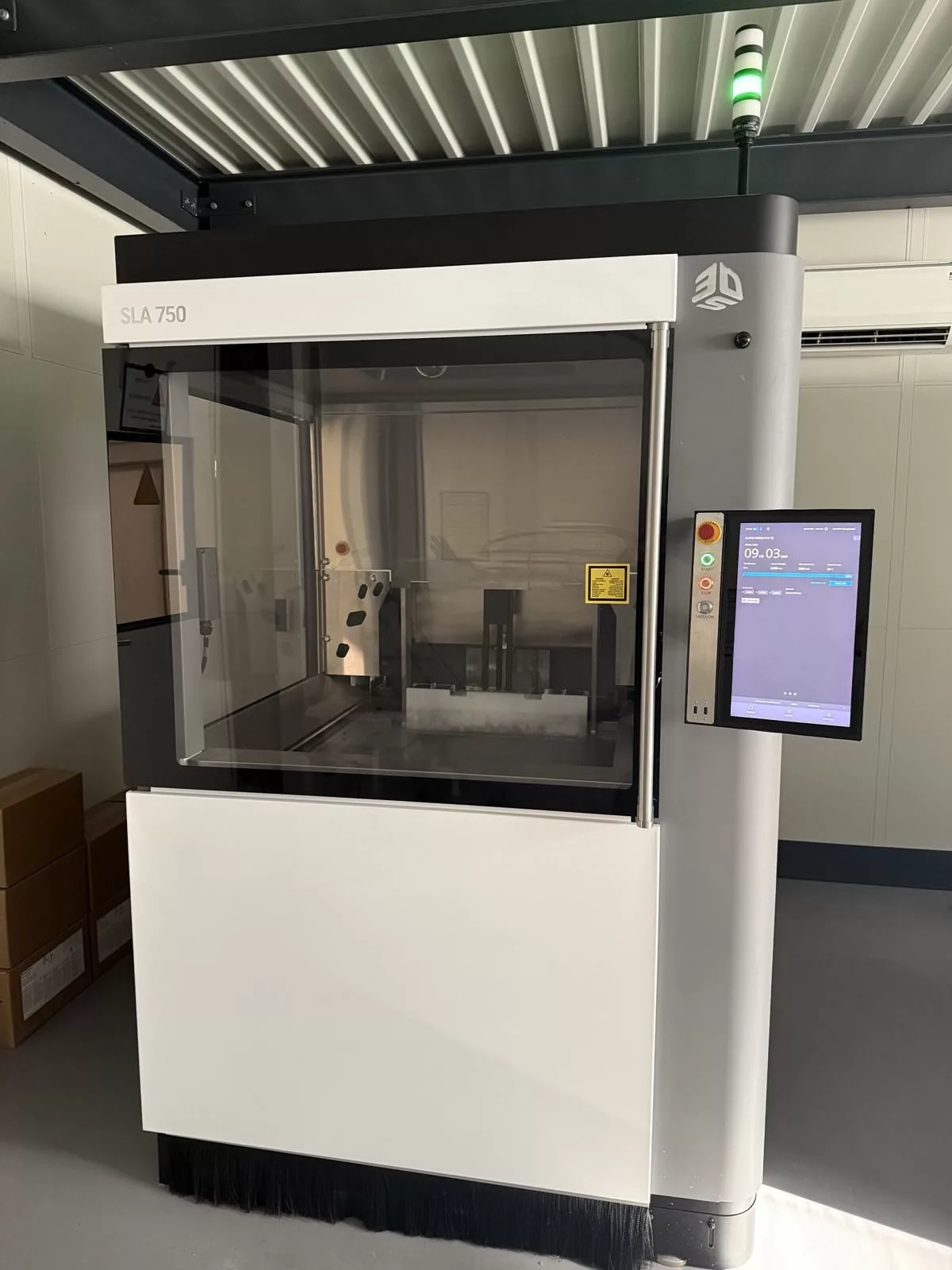

cirp expands production capacities with the SLA 750

cirp continues to invest in innovative technologies and sealed the purchase of the brand-new SLA 750 system from 3D Systems GmbH at formnext. Thanks to this investment, the plastics service provider from Heimsheim (Baden-Württemberg) is taking its 30 years of experience in additive manufacturing using stereolithography to the next level.

The SLA 750 impresses with its fast production time and maximum precision. Its build volume of 750 x 750 x 550 mm enables the simultaneous production of large containers, automotive headlights, and many small parts, for example. It is now in use at cirp to manufacture resilient plastic components. This expands cirp’s machine park to a total of 10 stereolithography systems.

Markus Gaißert, Head of Stereolithography at cirp, is delighted about the renewed collaboration with 3D Systems: “With the SLA 750, we can broaden our innovative portfolio even further and implement our customers’ wishes even faster.”

The SLA 750 integrates seamlessly into cirp’s existing process chain – from data management and construction to high-quality surface finishing. As a partner for plastic parts starting at a quantity of 1, cirp relies on stereolithography to enable outstanding surface quality and precise detail resolution overnight. cirp would like to express its sincere thanks to Frank Cremer and Deniz Okur from 3D Systems GmbH for this great collaboration.