Process

Your partner for plastic parts

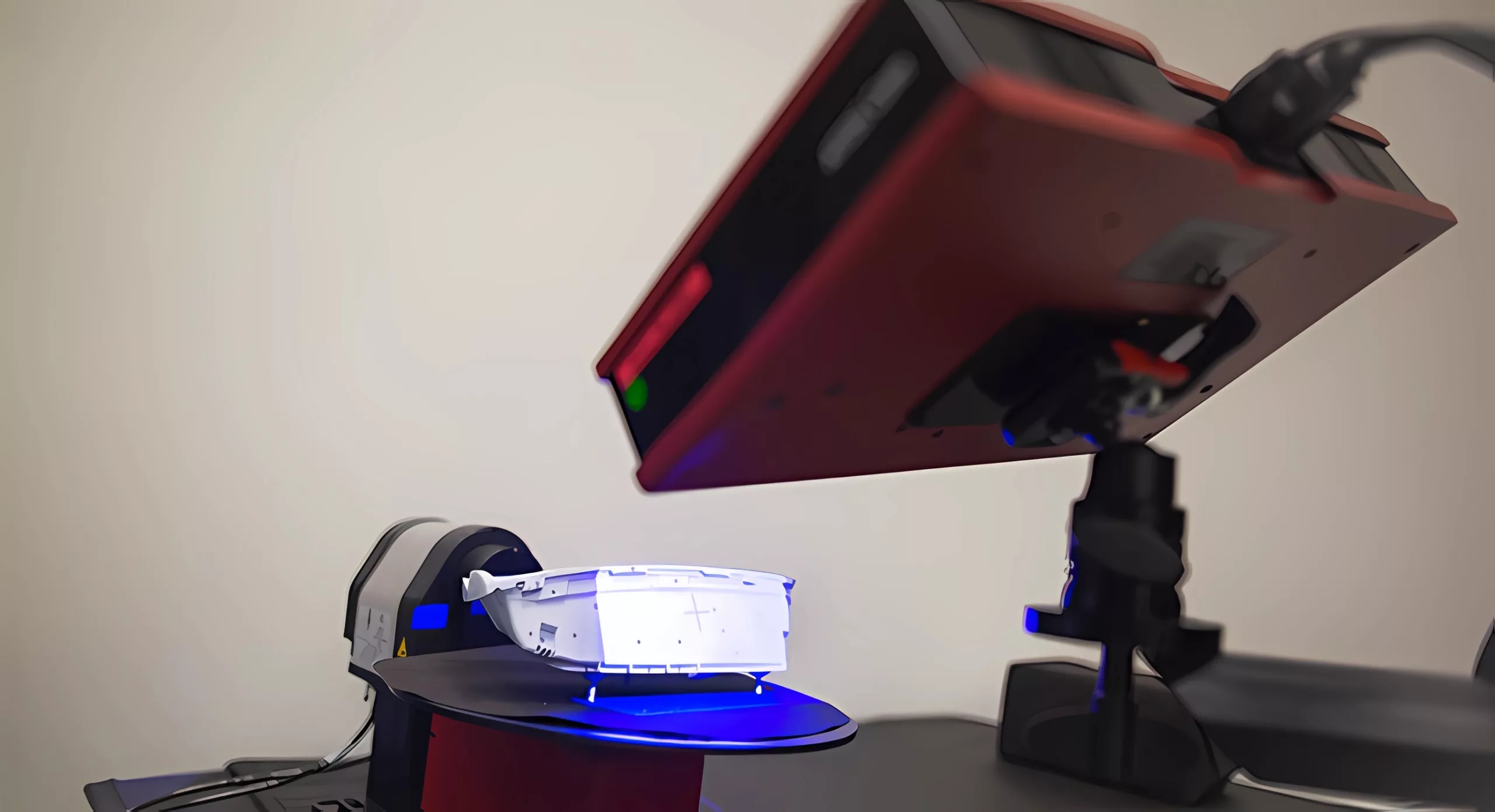

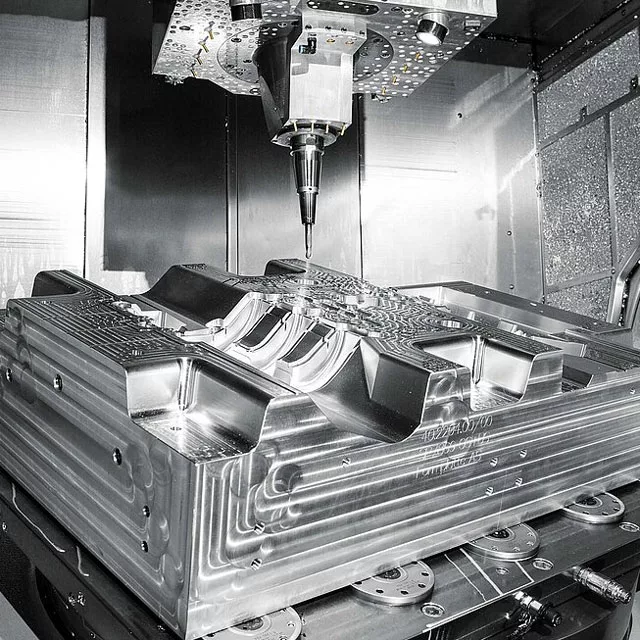

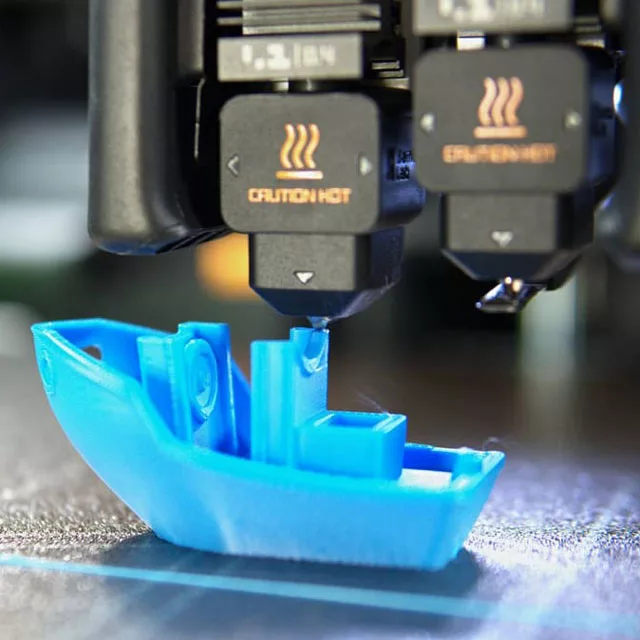

cirp GmbH supports its customers from the initial prototype design through to the start of series production. We work in the fields of development and design to create your CAD models, using the latest CAD/CAM systems and 3D scanning technologies. With our pool of state-of-the-art machines we also offer a variety of different generative and machining procedures in the fields of additive manufacturing, model making and mould construction as well as rapid tooling for creating your plastic pieces and tools that can be applied to your models and prototypes as required: