Our Processes

Metal casting

Our Processes

- Selective Laser Sintering (SLS)

- Powder Bed Fusion (MJF/SAF/HSS)

- Stereolithography (SLA)

- PolyJet (PJM) -EN

- CAD, manufacturing-oriented building component design & reverse engineering

- Measurement technology

- Metal casting

- Selective laser melting (SLM)

- RapidTooling (RT)

- CNC Machining

- Model making (MB)

- Vacuum casting (VAC)

- Fused Deposition Molding (FDM/FFF)

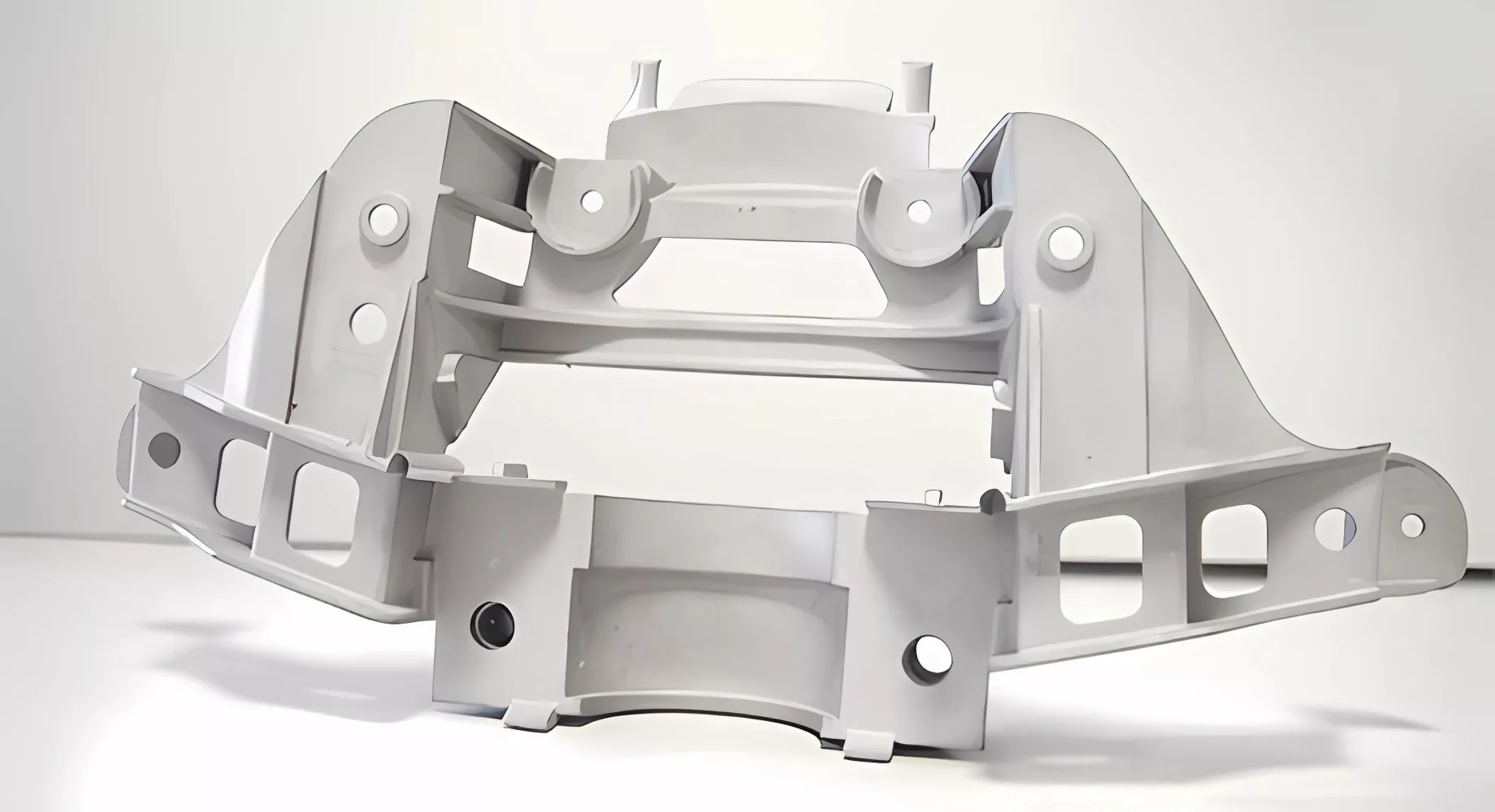

The vacuum differential pressure casting process makes it possible to cast metal prototypes with complex geometries at an early stage. All common aluminum and zinc die-casting alloys as well as various non-ferrous metals are available for this purpose. Functional prototypes with series production characteristics can be manufactured quickly and without high tooling costs using our vacuum precision casting process.

A differential pressure during the casting process ensures optimal filling of the casting mold. This means that castings with a wall thickness of less than one millimeter can also be produced. The structure is virtually pore-free and has a die-casting-like structure. The surface quality is comparable to that of series precision castings.