Our Processes

RapidTooling (RT)

Our Processes

- Selective Laser Sintering (SLS)

- Powder Bed Fusion (MJF/SAF/HSS)

- Stereolithography (SLA)

- PolyJet (PJM) -EN

- CAD, manufacturing-oriented building component design & reverse engineering

- Measurement technology

- Metal casting

- Selective laser melting (SLM)

- RapidTooling (RT)

- CNC Machining

- Model making (MB)

- Vacuum casting (VAC)

- Fused Deposition Molding (FDM/FFF)

Advantages of small-batch injection molding / Rapid Tooling (RT)

- Do you need near-series prototypes or a small series made from standard thermoplastics using injection molding?

- Are you looking for a cost-effective small series of plastic injection molded parts, ranging from several thousand to tens of thousands?

- Do you need resilient components with a delivery time comparable to that of 3D-printed components?

- Would you like to avoid lengthy delivery times and coordination with “steel toolmakers” and “series injection molders”?

- Would you like to procure locally with complete value creation in Germany (Stuttgart automotive region) and fast response times as well as flexible processes?

- Translated with DeepL.com (free version)

We generally work with standardized aluminum tool inserts, which are first manufactured in-house at our machining centers and then sampled on our injection molding machines with clamping forces ranging from 100 to 450 tons. This results in prompt completion of orders and the fastest possible turnaround time.

Delicate as well as large components can be manufactured in common series materials (thermoplastics) within a very short time. In addition, 2K components or components with subsequent assembly, as well as surface structures in accordance with DIN VDI 3400, are possible. Typical batch sizes are in the four-digit range for manual removal, but larger quantities are also possible with semi-automated or multi-cavity systems.

Translated with DeepL.com (free version)

Our entire project process takes place at our location in Heimsheim near Stuttgart.

Submitting an inquiry to us is very straightforward! All you need is a *.step file and the approximate quantities of your desired material. If your component is relatively simple, requirements can be quickly coordinated. For more complex components with shape and position tolerances or surface requirements, it is also advisable to create a drawing. If you have neither CAD data nor specific material knowledge, that’s no problem either, because our designers or specialists will be happy to advise you in the form of a workshop.

Each of our quotes is based on a manufacturability analysis, which draws on digital processes and the extensive experience of our tool designers and injection molders. Every quote is therefore based on a tool and demolding concept that allows us to estimate the manufacturing costs of the tool on the one hand and the cycle times for component production on the other. If the data is not yet ready for production, we will at least provide you with a guide price quote and, if necessary, we will be happy to go through it with you in a workshop or assist you with our expertise in injection molding-compatible component design.

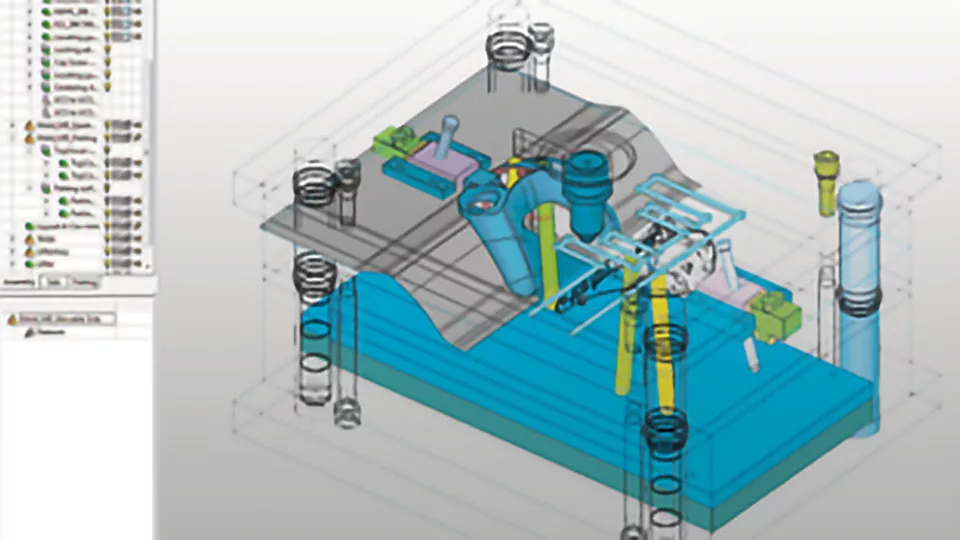

As soon as the customer has given the go-ahead, our tool designers start their work. Depending on factors such as tolerances, demolding concept, material, and many other aspects, they develop the optimal tool concept and implement the project requirements in reality. This work step is ultimately verified by a dual control principle. This means that the tool is checked and approved by a colleague before production begins.

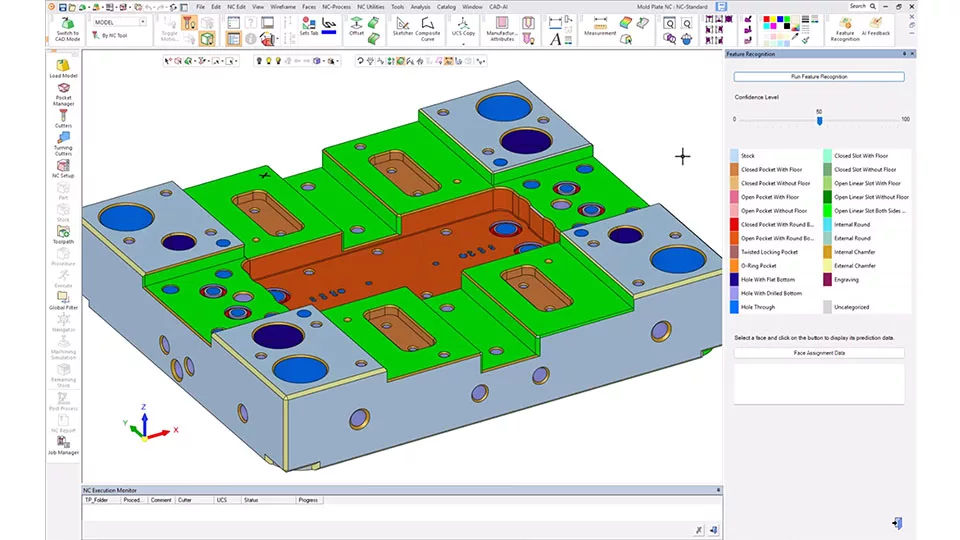

Once the tool design has been approved internally, the next step is CAD/CAM programming so that the corresponding machine programs can be written for our 3- to 5-axis machining centers. This is a routine step for us, but it also requires a great deal of expertise, because only with the right milling strategies can you quickly and cost-effectively produce dimensionally accurate tools and thus also components.

Injection molding tools consist of a wide variety of components. Not all of them are milled by us. For example, ejector pins are ordered as standard parts, cut to the correct length by our toolmakers, and, if necessary, adapted to the surface contour. In addition, the tool is assembled here for the first time and then fine-tuned. This is the only way to achieve perfectly coordinated tool components.

The picture from our technical center clearly shows our workflow. On the left are the machining centers for manufacturing the tool molds and inserts. At the back are our toolmakers and on the right are the injection molding machines. These are all fully electric to achieve perfect process stability. Here, the components are then injection molded on the appropriate machine. Our machines are designed with different clamping forces and injection volumes so that the right machine is always available.

In order to be able to check the quality of our production at any time, our measuring laboratory is located in the air-conditioned office directly next to the production area. Here we can also create initial samples (EMPB) based on VDA levels 0, 1, 2 or according to our customers’ specifications. Our measuring room is equipped with two grazing light projectors for optical surface measurement and a tactile measuring machine. In addition, we have a device for measuring surface roughness and a wide range of different measuring standards. And if a component cannot be easily measured optically or tactilely, we have an established process with a service provider for industrial computed tomography (CT). After component capture, we can evaluate the components as usual in our Carl Zeiss software suite (formerly GOM). You can find more information about our measuring room here.

Sind alle QM-Themen durchlaufen, landen die Bauteile in unserem Teilefinish. Dort werden zum Beispiel Angüsse abgetrennt oder die Bauteile nach Kundevorgabe etikettiert und/oder sicher verpackt. Nur so gehen die Teile auf den Weg zu unseren Kunden oder deren Auftraggebern…

Our machines

Material data

A wide range of all common thermoplastic series materials from various manufacturers with a wide variety of material properties are available for injection molding.

Due to the diversity of materials, we are happy to offer you detailed advice.

We would be pleased to advise you on the selection of the most suitable material for your specific application.

Referencen

The Stuttgart-based start-up aucobo offers leading people-oriented smart wearable solutions for industrial shop floor management. Automated and intelligent information distribution enables significantly more effective collaboration thanks to a new type of networking between people and machines, ensuring comprehensive digitalization in production and logistics. The summarized information is transmitted directly to the wrist via smartwatch. A protective cover is designed to reliably protect the end device from damage and dirt in production areas. As a project partner, cirp supports the company in the manufacture of the cover with its complete service package, from 3D digitization and design to the selection of materials and technology to the finished product. The first prototype was made of TPU. The series part is currently being manufactured using a skin-friendly material in an injection molding process.

Project: cirp-EXPRESS 2K series tool within just one week

With the evation drive, FAZUA presents an electric drive system that is primarily aimed at sporty requirements while still conveying the natural riding experience of a non-motorized bicycle. However, the eBike, which was already scheduled for delivery, identified a need for further development that would not have allowed for on-time delivery under normal circumstances. cirp was able to provide significant support here with its rapid tooling process. With a few small but crucial adjustments, the component was optimized so that within a week, both the injection mold for the hard component and the matching mold design for the soft component could be implemented and sampled. Within this period, the first 1,000 parts of the total 15,000 2-component parts produced to date were also manufactured in-house.

Project: cirp-EXPRESS 2K series tool within just one week

Material: 2K components (hard/soft)

Individually adjustable product elements enable a comfortable fit for the end consumer. Multiple rows of fasteners also support width adjustment and compensate for material fatigue. cirp currently manufactures fastener elements in translucent white and blue on its injection molding machines. The end position of the functional components can be easily and securely determined by a detachable clip connection. Contact with hot water and washing in the washing machine for cleaning are no problem.

Project: cirp-EXPRESS 2K series tool within just one week