Our Processes

Stereolithography (SLA)

Our Processes

- Selective Laser Sintering (SLS)

- Powder Bed Fusion (MJF/SAF/HSS)

- Stereolithography (SLA)

- PolyJet (PJM) -EN

- CAD, manufacturing-oriented building component design & reverse engineering

- Measurement technology

- Metal casting

- Selective laser melting (SLM)

- RapidTooling (RT)

- CNC Machining

- Model making (MB)

- Vacuum casting (VAC)

- Fused Deposition Molding (FDM/FFF)

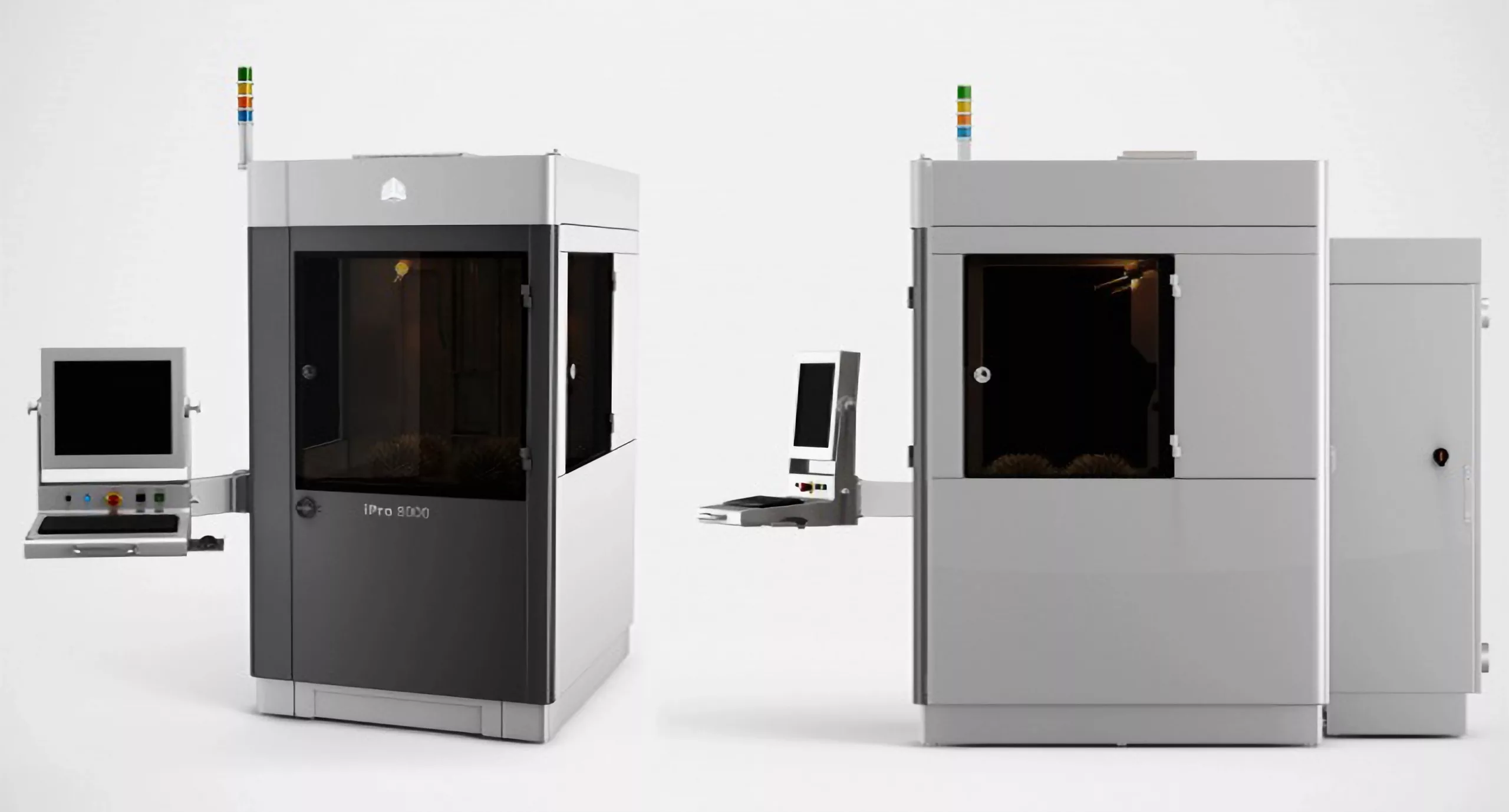

Our stereolithography process allows you to create precise and complex components. Through targeted, layer-by-layer curing of liquid, UV-sensitive resins, the actual model achieves a high degree of dimensional and shape accuracy with a general deviation of +/- 0.2%. For small components smaller than 100 mm, a general deviation of +/- 0.2 mm applies. In addition, the surfaces of stereolithography parts can be optimally improved through manual post-processing. Stereolithography is particularly suitable for checking design, construction, assembly, and simple functions for batch sizes of up to five parts. The turnaround time is two to four working days.

Mechanical properties

We use different photopolymers with different properties for our SLA models, depending on requirements and area of application.

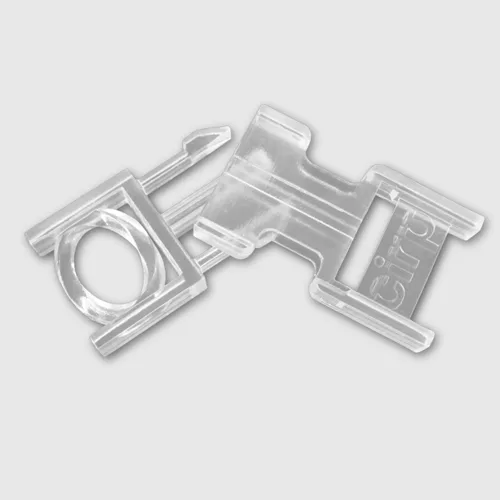

WaterShed® XC 11122 is suitable for the production of solid, hard, moisture-resistant, ABS-like components. Crucially, components made from WaterShed® XC 11122 are almost as clear and transparent as glass, simulating transparent plastics.

The plastic parts made from it are extremely durable and impact-resistant. Due to its exceptional clarity and transparency, the material is particularly well suited for headlights.

Accura® 25 is an accurate and flexible material that can simulate both the properties and aesthetics of polypropylene.

Accura® Xtreme material resembles durable cast ABS plastic in appearance and surface texture. This robust and versatile material is particularly suitable for functional components that need to be especially durable.

Somos® EvoLVe 128 is suitable for manufacturing extremely robust, strong, high-precision, moisture-resistant components similar to ABS or polypropylene. The material is virtually indistinguishable from traditional thermoplastics and is particularly suitable for mechanically stressed parts.

CRL 52 White is the symbiosis of robustness, impact resistance, and functionality. The material is ideally suited for ABS-like components. The components are particularly suitable for functional prototypes, dashboards, snap-fit moldings, and master models for molding processes.

Surface technology and assembly

Our trained model makers will assist you with various surface finishes and assembly work to ensure that your component meets your expectations. We will work with you to determine the level of detail, time required, and effort involved.

Finish (grob) ist unser Standard im SLA. Dies bedeutet, dass bei diesen Bauteile die im Druck nötige Stützstruktur entfernt ist un d die Anknüpfungspunkte einmal verschliffen wurden. Fertigungsbedingte Baustufen bleiben hier sichtbar.

Soll ein Bauteil glatte Oberflächen erhalten, muss dieses noch immer noch von Hand und mit Hilfe von Schleifpapier erfolgen um zum Beispiel die fertigungskostenbedingten Baustufen oder Anbindungspunkte der Stützstruktur zu entfernen. Hier ist viel Erfahrung und Gefühl gefragt. Diese Bearbeitung ist die Vorstufe um die Bauteile auch in höchster Qualität lackieren zu können.

Wir polieren Bauteile auf Glätte, Glanz oder Hochglanz. Durch das Top Finish der SLA-Teilen aus WaterShed® XC 11122 oder Accura® ClearVue kann eine hohe Transparenz erzeugt werden.

Mit Hilfe unserer Lackierkabine können wir Lacke in in den Anforderungen der Automotive Industrie herstellen. Ja nach Material u gewünschten Resultat wir vorab die Bauteile oder verwenden zusätzlich Struktur oder Klarlacke. Fast nichts ist unmöglich. Zudem können wir mit unserem eigenen Farbmischsystems viele RAL-Farben schnell selber anämischen und wir haben zudem direkten Zugriff auf Lacke diverser deutsche Automotive OEMs.

Markierungen, Schriften, Symbole oder Logos können entsprechend auf die Kunststoffteile aufgebracht werden.

Das cirp-Team entlastet Sie auch im Bedarfsfall bei der Montage Ihrer Baugruppen. Dazu gehört unter anderem auch die Montage einzelner elektrotechnischer Komponenten und Zukaufteilen.

| Material designation | Accura® 25 | Somos® EvoLVe 128 | Accura® Xtreme | Accura® ClearVue | WaterShed® XC 11122 |

|---|---|---|---|---|---|

| Color | white | white | grey | transparent | transparent |

| Hardness [Shore A/D] | 80 | 82 | 84 | ||

| Flexural modulus [MPa]* | 1380 – 1660 | 2654 | 1520 – 2070 | 1560-2040 | 2205 |

| Flexural strength [MPa]* | 55 – 58 | 57 – 71 | 53 – 67 | 68,7 | |

| Tensile modulus [MPa]* | 1590 – 1660 | 2964 | 1790 – 1980 | 2030 – 2220 | 2770 |

| Tensile strength [MPa]* | 55-58 | 56,8 | 38 – 44 | 41 – 46 | 50,4 |

| Elongation at break [%]* | 13 – 20 | 11 | 14 – 22 | 4-7 | 15,5 |

| Notch impact strength [kJ/m7]* | 19 – 24 | 38,9 | 35 – 52 | 43 – 67 | 25 |

| Water absorption [%] | 0,40 | 0,35 | |||

| Density [g/cm3] | 1,19 | 1,12 | 1,19 | 1,17 | 1,12 |

| HDT @ 0.45 MPa [°C]* | 58 – 63 | 52,3 | 62 | 46 | 50 |

References

Kevin is a laboratory assistant for simple tasks and for loading laboratory equipment. Among other things, the laboratory robot transports a plate with several reagents from device to device. Kevin was developed by the Fraunhofer Institute for continuous operation on weekends, holidays, and at night. The entire production and assembly of all cladding components for the first prototype was carried out by cirp. The housing consists of SLA components that have been sanded, painted, and assembled. The bumpers in the lower area are made of soft material using vacuum casting.

Copyright Fraunhofer Institute for Manufacturing Engineering and Automation IPA / cirp GmbH

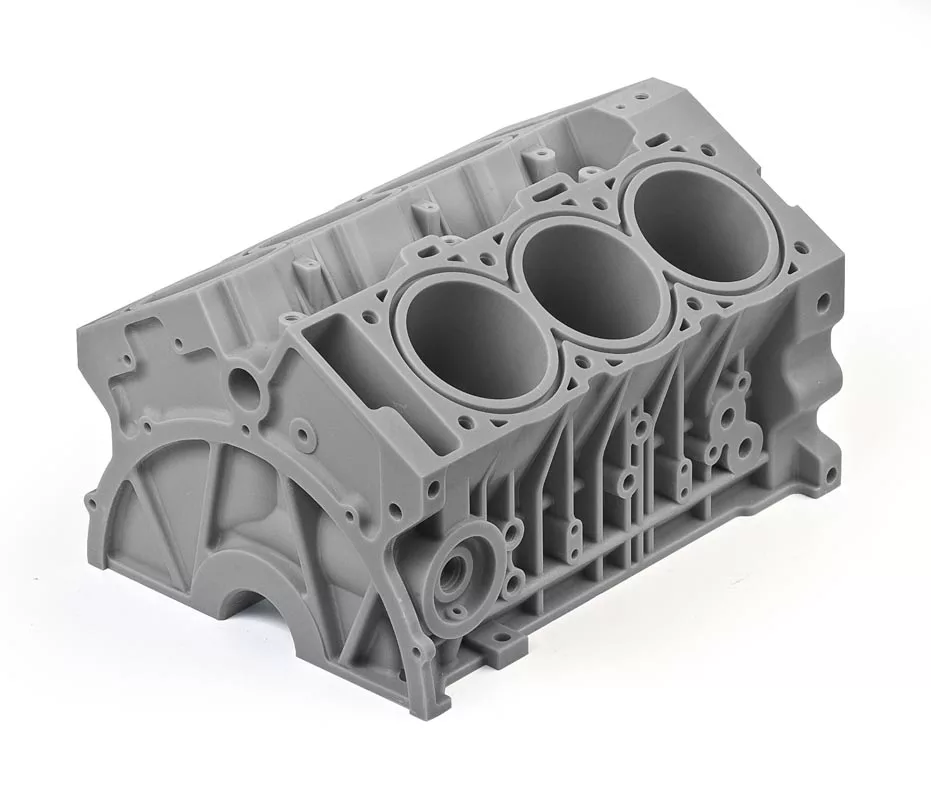

1:1 Model of a V6 engine block

Material: Accura® Xtreme

Scale model for the manufacturer, which we were able to produce entirely on our own, from data preparation to assembly. The entire body, as well as the rims and tires, were manufactured using the SLS process. It was then finished and painted before assembly. Some details, such as the license plate and manufacturer emblems, were produced using PolyJet.

Model of a piston manufactured in Somos® WaterShed® XC 11122. This was required for component testing in order to trace flow paths through the integrated ring for cooling and to compare them with the simulations.

The diamond was created as a visual model.

Material: Somos® WaterShed® XC 11122