3D-Printing

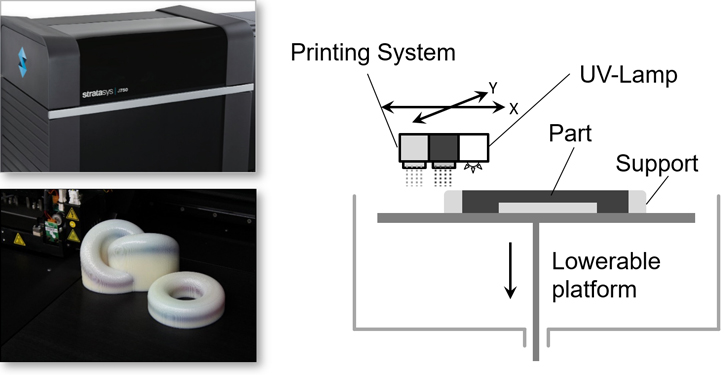

With our 3D-Printing method you can provide high-precision components. Both photopolymer resins and rubber materials can be used for the production. The prototypes show smooth, durable surfaces with excellent detail precision and extraordinary surface condition. Thanks to the high quality of the result and the flexibility in terms of multi-material printing you're able to reproduce the visual, haptic and functional properties of an unusually wide range of end products as accurately as possible.

3D-Printing is particularly suitable for design models, master patterns for follow-up actions like vacuum moulding, precision and sand casting master patterns for cast resin tools, design review and initial samples with batch sizes up to 5 units.

| Stratasys Ltd. - Stratasys J750 Build size (X x Y x Z) 490 x 390 x 200 mm Number of systems: 1 |

| Stratasys Ltd. - Objet500 Connex Build size (X x Y x Z) 500mm x 400mm x 200 mm Number of systems: 1 |

| Stratasys Ltd. - Objet Eden 500V Build size (X x Y x Z) 500mm x 400mm x 200 mm Number of systems: 1 |

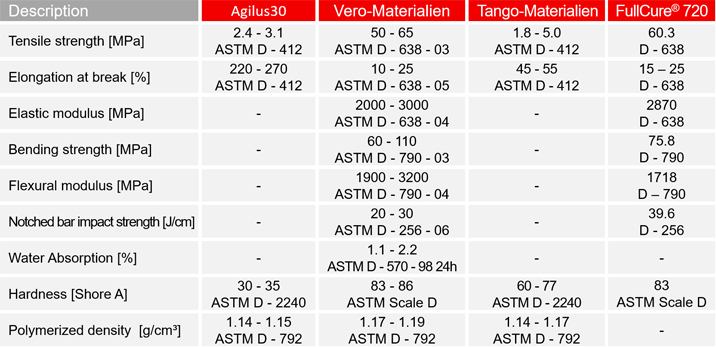

| FullCure® 720 | The FullCure® family of materials consists of several elastic and not elastic resins. The material is suited for standard applications and has exceptional technical characteristics by transparent colouring (yellow cast). Furthermore, complex geometries including bulging and undercutting can be implemented with the FullCure® support material. |

| Vero-materials | With its opaque colours and optimised mechanical properties the material provides an outstanding reproduction of detail as well as a wide range of applications. |

| Tango-materials | Due to the material's flexibility and elasticity it results in an authentic "Touch and Feel-effect" for all designs. |

| Agilus 30-materials | Agilus 30 is a PolyJet photopolymer that is outstandingly tear-resistant and can withstand repeated bending and twisting. It is suitable for the production of longlived, highly flexible, high-precision pieces. Agilus 30 simulates the appearance, feel and function;of rubber, and has a Shore A value of 30 in clear or black. It is ideally suited for design validation. The components are particularly suitable for rubber-like products and medical models. |

Under no circumstances can the published information about the material data be considered as express warranty or otherwise. The application of these information and references as well as the decision on the suitability of any product for special applications is in all cases subject to the sole responsibility of the user.

|

The DIMAP project focuses on the development of novel ink materials for 3D multi-material printing by PolyJet technology.

cirp is responsible for 3D printing of design-studies, final demonstrator and evaluation of final prototype in view of exploitation. The main task is to test and evaluate the results for use in additive manufacturing processes for daily industrial applications and to support these developments. | |

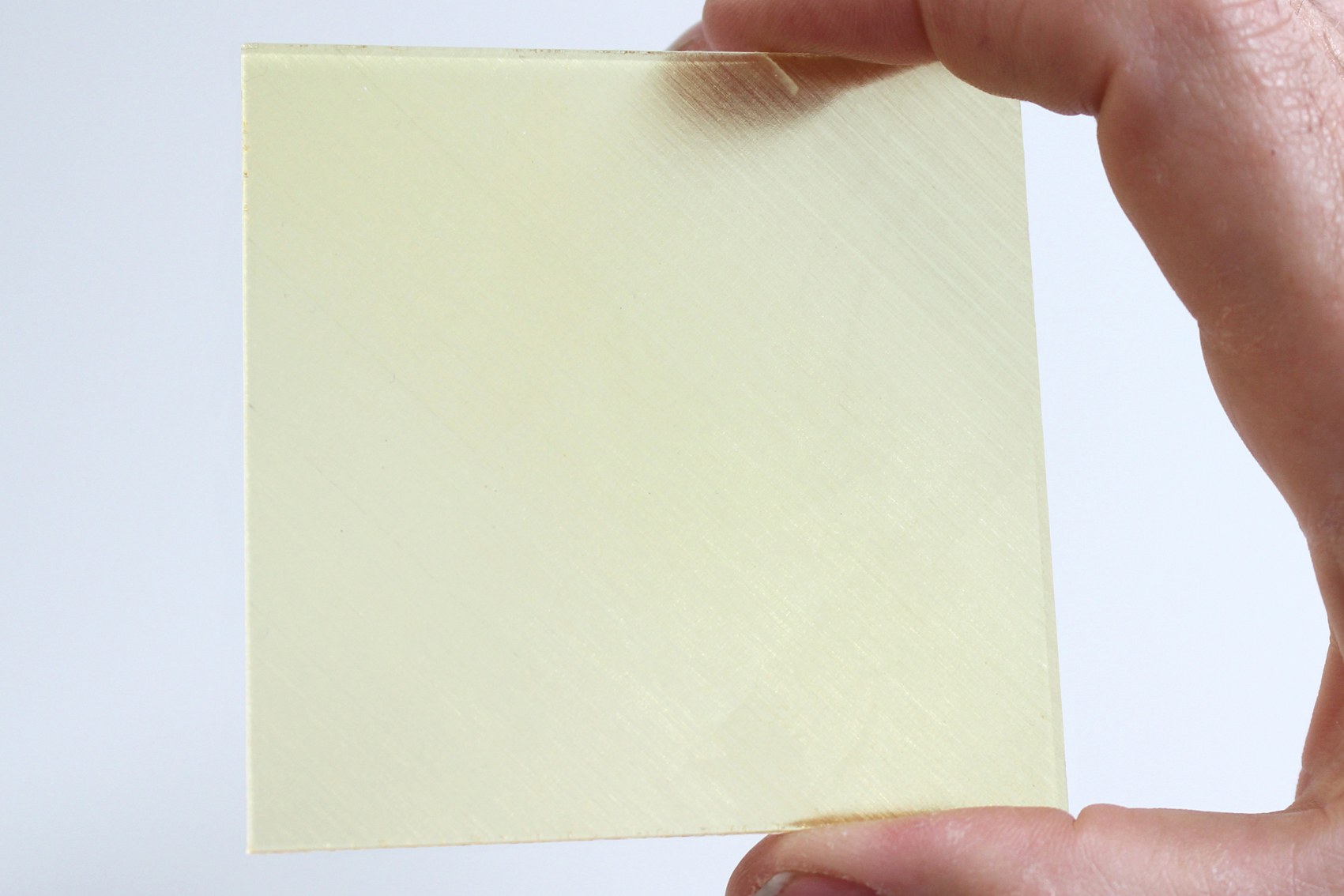

| Within the DIMAP-research project, for the first time polyimide plastics were printed successfully by cirp GmbH using PolyJet™ technology (Stratasys® Ltd., Israel). Polyimide plastics are high-performance plastics with excellent mechanical and thermal properties. The Polyimide-based ink has been developed by the project partner Soreq, Israel (patent pending). The DIMAP-research project for new materials is funded within the European Horizon 2020 program for research and innovation under grant agreement no 685937. |

|

Beteiligte Partner PROFACTOR, Stratasys, KIT, BOREALIS, TIGER, FESTO, PHILIPS, JKU, SOREQ, PV Nano Cell, TECNAN  For more information see For more information see  (dimap-project.eu) (dimap-project.eu) | |