Selective Laser Sintering (SLS)

Sample parts and prototypes, which are verifiable in their geometrical form as well as in

their functionality and show mechanical property, are manufactured using laser sintering. In the process a

polyamide powder is fused in layers by a laser. The real model achieves a high dimensional and contouring

accuracy with a general deviation of +/- 0,5%. For small components with a size of less than 30 mm, there is a general deviation of +/- 0.15mm.

A very good surface condition can be achieved by

reworking and varnishing the polyamide models. The laser sintering process is most suitable for the

production of functional prototypes with snap-fits, integral hinge and clip connections for functional

models, installation trials, design review and rapid manufacturing with lot sizes up to 250 pieces.

Laser sintering allows fast production of prototypes for far-reaching functional examinations. The

mechanical and thermal properties comparatively enable the parts to endure extreme stress. The processing

time is 3 to 5 work days.

| EOS GmbH - EOS P 770 Build size (X x Y x Z) 700 x 380 x 580 mm Number of systems: 2 |

| EOS GmbH - EOS P 760 Build size (X x Y x Z) 700 x 380 x 580 mm Number of systems: 1 |

| EOS GmbH - EOS P 396 Build size (X x Y x Z) 340 x 340 x 600 mm Number of systems: 3 |

| EOS GmbH - EOS P 395 Build size (X x Y x Z) 340 x 340 x 600 mm Number of systems: 1 |

| EOS GmbH - Formiga P 100 Build size (X x Y x Z) 200 x 250 x 330 mm Number of systems: 1 |

The process uses a polyamide powder which is subjected to localised melting in layers using a laser beam.

Standard materials such as fine polyamide comparable to PA 12 are being used in the EOSINT machines. They are available without glass filling as PA2200 or with glass filling as PA 3200GF. The polyamide PA 2200 is certificated as biocompatible. | |||

| Alumide | Alumide is a metallic grey, aluminium-filled nylon 12 powder with excellent dimensional accuracy. . It is suitable for the production of highly robust, rigid, high-precision pieces. The material is suitable for a range of applications. The components are particularly suitable for applications in automotive manufacturing (e.g. wind tunnel tests), as well as for the construction of gauges and equipment. | ||

| PA2200 | PA2200 is a fine white powder based on nylon 12. It is suitable for the production of highly robust, strong, high-precision, high-performance pieces. The material is biocompatible and certified for contact with food. The material is particularly suitable for models and assemblies with high demands with respect to mechanics and fracture behaviour. Typical applications for this material include moving connectors, high-performance pieces, prostheses and orthoses. The components work particularly well as medical models and products. | ||

| PA2201 | PA 2201 is a white, slightly translucent nylon 12 powder. It is suitable for the production of highly robust, strong, high-precision, high-performance pieces. The material meets the FDA’s strict requirements, and is suitable for a wide range of applications in the fields of medicine and healthcare. The components work particularly well as medical models and products. | ||

| PA3200GF | PA 3200 GF is a white, glass bead-filled nylon 12 powder that combines rigidity with good elongation at rupture. It is suitable for the production of highly robust, rigid, high-precision pieces. The material stands out on account of its good dimensional stability under heat, and is particularly suitable for pieces subjected to thermal stress. The components work particularly well as end products in the engine areas of vehicles. | ||

| TPU 1301 | TPU 1301 is a white, thermoplastic polyurethane powder with rubber-like elasticity. It is suitable for the production of highly flexible, abrasion-resistant, high-precision pieces. The material is particularly suitable for bending parts. Typical fields of application include shoe soles, damping elements, orthopaedic inserts, seals, pipes, grips, bellows and tyres. | ||

Under no circumstances can the published information about the material data be considered as express warranty or otherwise. The density and mechanical properties may vary depending on the light exposure parameters and the x, y, z positioning of the test pieces. The application of these information and references as well as the decision on the suitability of any product for special applications is in all cases subject to the sole responsibility of the user.

Our trained model makers support you with different surface finishes and assembly work in order to ensure that your prototype is as close as possible to the future series-produced piece. We define the level of detail in consultation with you.

| Polishing/top finish | We can polish components to smoothness, gloss or high-gloss. SLA parts made from WaterShed® XC 11122 or Accura® ClearVue can be given a top finish in order to make them transparent. |

||||||||||||||||||||||||||

| Chemical smoothing | Chemical smoothing seals the surface, and pieces are smoothened, sealed and made resistant to dirt. The mechanical properties are also improved, since smoothing the edges of the layers reduces the notching effect. Dyed pieces last even longer following treatment. The properties of biocompatible materials, for example in the food industry or medical products,are preserved. |

||||||||||||||||||||||||||

| Infiltration | Infiltration involves dipping pieces in transparent epoxy resin. Epoxy infiltration provides air and water-tight sealing that can withstand high temperatures or chemicals. No material is deposited as part of the infiltration process, which means that it does not interfere with colouring. |

||||||||||||||||||||||||||

| Colouring | cirp now offers a wide range of colours. The components are fully coloured up to a depth of around 0.3 mm. The colours are resistant to UV rays, water and abrasion. No material is deposited as it would be in the case of painting or metal coating.

| ||||||||||||||||||||||||||

| Painting | The SLA parts can be painted in any RAL colour. Special paint applications are also possible. | ||||||||||||||||||||||||||

| Metal coating | Galvanic coating or aluminisation are used to achieve results that range from chrome-like to high-gloss. The substrate also ensures outstanding thermal and electrical conducting properties. |

||||||||||||||||||||||||||

| Fitting of threaded inserts | Various threaded inserts may be fitted into the laser-sintered piece should you wish. |

||||||||||||||||||||||||||

| Assembly | If necessary, the cirp team will also help you put together your component assemblies. This also includes the assembly of individual electronic components and purchased parts. |

3D-printed base stand

purmundus is a design brand registered by cirp, and offers an innovative portfolio of 3D-printed table and standard lamps. As a technical centrepiece, the base stand is integrated into the socket of the designer lamp, and in addition to affixing the carbon-fibre rod and mounting the plates, serves as a pressure mechanism for the on/off switch.

Project: Mechanical series production component for a designer lamp

Material: PA2200

Product link

Product link  (purmundus.en)

(purmundus.en)

Copyright purmundus

Additive manufactured expansion head

The additive manufactured expansion head will be used to spread contact lens blisters. The transfer process is carried out by a Delta-Robot. The SLS material PA2200 allows us to manufacture thin-walled structures that are flexible enough to compensate for the movement of the expansion head.

Project: Custom job

Material: PA2200

Further informations about Harro Höfliger Verpackungsmaschinen GmbH

Further informations about Harro Höfliger Verpackungsmaschinen GmbH  (hoefliger.com)

(hoefliger.com)

Copyright Harro Höfliger Verpackungsmaschinen GmbH / Nico Hjordt

Ballet slipper with soft shoe sole

For professional use, a pair of flats rarely lasts longer than one day. Sophia Lindner, as a product designer, has developed a patentable solution of a lasting design together with experts on the field of sports medicine, ballet dancers and shoemakers.

Project: functional prototype of a soft shoe sole

Material: TPU 1301

Product link

Product link  (actable.me)

(actable.me)

Copyright Sophia Lindner / cirp GmbH

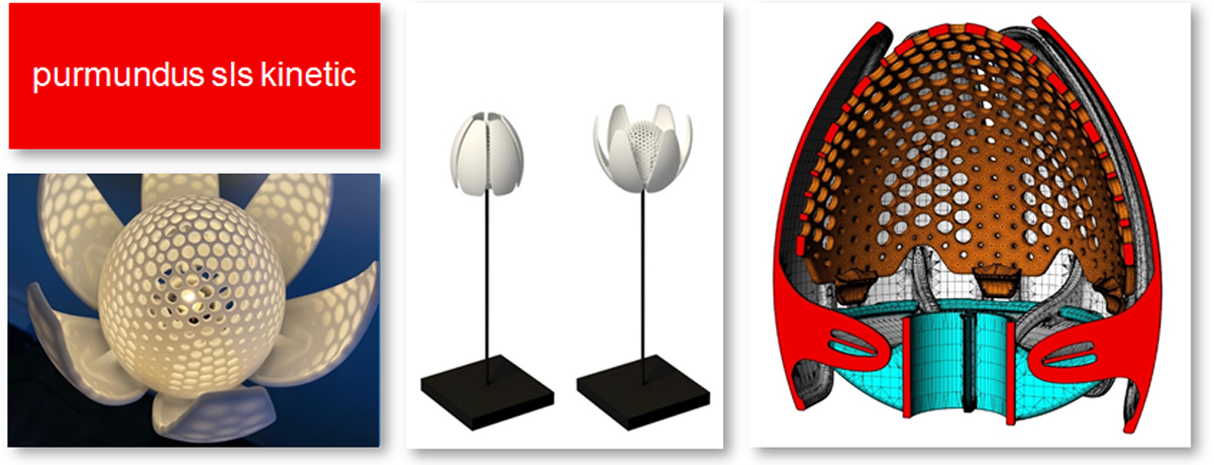

Kinetic sls bistable lampshade

The kinetic sls standard lamp invites interaction. Its perforated core is entwined by a second, shifting level of translucent leaves that take up the special light structure. Simply pulling on two opposing leaf points opens the shade, and makes way for the light to create a futuristic shadow play. In this way, the kinetic sls combines multifaceted nuances of lighting with an innovative technical principle. The LED lamp is compatible with all sls series lampshades.

Design: Frank Kleemann

Material: PA2200

Product link

Product link  (purmundus.de)

(purmundus.de)

Copyright purmundus