Stereolithography

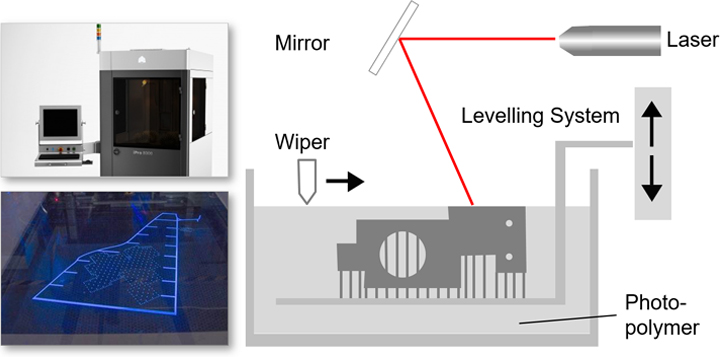

Precise and complex components can be fabricated with our stereolithography procedure. With specific, in-layers-hardening of liquid polymer caused by UV-laser light the real model achieves a high dimensional and contouring accuracy with a general deviation of about +/- 0,2%. For small components with a size of less than 100 mm, there is a general deviation of +/- 0.2mm. Additionally, there is the possibility to optimally improve the surfaces of stereolithography parts by manual correction.

Stereolithography is most suited for verification of design, construction, assemblies and simple functions with lot sizes of up to 5 pieces. The processing time is 2 to 4 work days.

| 3D Systems - IProTM8000 SLA®Center Build size (X x Y x Z) 650 x 750 x 550 mm Number of systems: 2 |

| 3D Systems - SLA Viper Build size at standard resolution (X x Y x Z) 250 x 250 x 250mm Number of systems: 1 |

| 3D Systems - SLA 7000 Build size (X x Y x Z) 500 x 500 x 550 mm Number of systems: 2 |

| 3D Systems - SLA 5000 Build size (X x Y x Z) 500 x 500 x 550 mm Number of systems: 2 |

The process uses a liquid resin that is hardened in layers using a laser beam

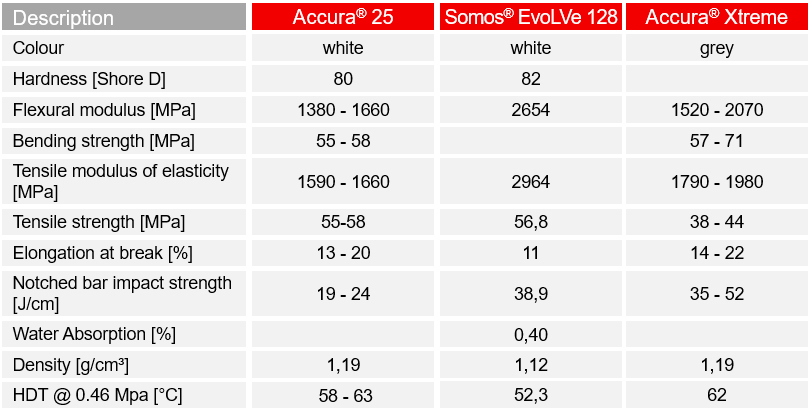

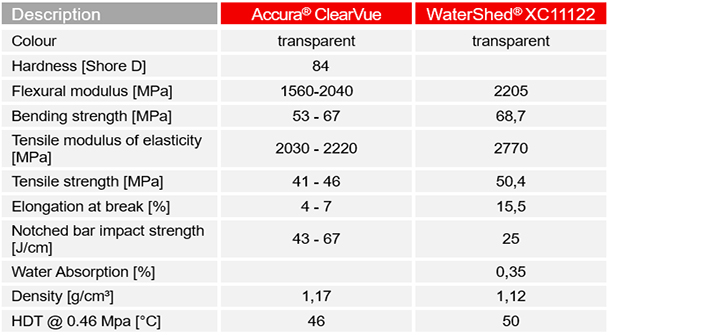

We use different photopolymers with different properties for our SLA models depending on the requirements and the field of application. | |||

| WaterShed® XC 11122 | WaterShed® XC 11122 is suitable for producing rigid, hard, waterproof components similar to ABS. One crucial property is that components made from WaterShed® XC 11122 are almost as clear and see-through as glass, and therefore simulate transparent plastics. | ||

| Accura® ClearVue | The plastic parts made from it are extremely durable and resilient. The material's particular clarity and transparency make it particularly suitable for use in headlights. | ||

| Accura® 25 | Accura® 25 is a precise and flexible material that can be used to simulate both the properties and appearance of polypropylenes. | Accura® Xtreme | Accura® Xtreme has the appearance and surface finish of a durable cast ABS plastic. This robust and versatile material is above all intended for functional components that have to withstand particularly strong forces. |

| Somos® EvoLVe 128 | Somos® EvoLVe 128 is suitable for producing extremely robust, rigid, high-precision, waterproof components similar to ABS or polypropylene. The material is virtually indistinguishable from traditional thermoplastics, and is particularly suitable for functioning components, socket/snap connectors and gadgets. | ||

Under no circumstances can the published information about the material data be considered as express warranty or otherwise. The application of these information and references as well as the decision on the suitability of any product for special applications is in all cases subject to the sole responsibility of the user.

Robot Kevin the laboratory assistant

Kevin is a laboratory assistant for the performance of simple tasks, and for loading laboratory equipment. Amongst other things, the laboratory robot will transport a plate with several reagents from one device to the next. Kevin was developed by the Fraunhofer Institute – for continuous operation on weekends, public holidays and at night as well. Complete production and assembly of all cladding components for the first prototype was handled by cirp. The housing consists of SLA components that have been ground, painted and assembled. The bumpers at the bottom are made of a soft material by means of vacuum casting.

Copyright Fraunhofer Institute for Manufacturing Engineering and Automation IPA / cirp GmbH