Metal casting

Metal casting

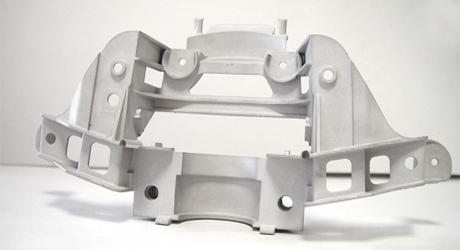

Thanks to the process of differential pressure casting metal prototypes with complex geometries can be manufactured at an early stage. All current aluminium and zinc die casting alloys as well as different non-ferrous metal are available. Vacuum moulding enables manufacturing functional prototypes with serial characteristics fast and without high tooling costs.

A differential pressure during the casting process is responsible for an optimal filling of the cast mould. Thus parts can be fabricated with a wall thickness of less than 1 mm. The configuration is almost free of pores and features a structure like the one achieved by pressure casting. The surface quality is comparable to a serial investment casting.